Our first year selling flowers at the farmers market, we sold straight bunches of sunflowers, zinnias, etc. Then I saw a vendor at market making beautiful wildflower bouquets (legitimately wildflowers from the side of the road), and people loved them. Having always been into art, we decided bouquet making was definitely going to become a part of what we offered. Last year, we made more than 14,000 bouquets for grocers and farmers markets.

When we started making bouquets for farmers market, we would just take the flowers to market separately and make all bouquets on demand. This method worked until we started to have a line and it required three people to keep up. When we enrolled in a second Saturday market, we knew we had to start pre-making bouquets. Now we take most crops to market pre-bunched, only requiring one person to do each market most days. The only things we now take loose to market are: dahlias if there are any extra, salvia, sunflowers, or pumpkin on a stick. Our pre-bunched flowers include zinnias, lisianthus, lilies, celosia, and mums — all sleeved. This helps protect the flowers from customers’ mishandling, but also gives people the same experience they would have if they saw our product in the grocery store.

Below: From harvest to delivery, having systems in place is essential to profitability of a bouquet business. Here, an employee at Sunny Meadows Flower Farm unloads buckets of just-harvested flowers into the packing shed. Finished bouquets are on the shelves at right.

At first we designed every bouquet, which took way too long and cost a lot in labor. Everyone would pick out of the buckets, and we would all hang out in the garage and compare bouquets while we were working, taking about 4 minutes per bouquet per person. Then we attended an ASCFG conference and learned that people were making a bouquet a minute?! We knew when we expanded into grocery sales, we were going to have to step it up, so we implemented some different techniques. Now we can make one bouquet per minute.

With bouquets, time is money. If you break down the cost per stem, you are getting paid less than you would charge wholesale, and that doesn’t include the labor, sleeve, and sticker. The benefit of grocery sales is the volume you can sell. Without grocery sales, we would grow far less, but it makes sense for the profit/square foot—especially if you can make speedy bouquets.

Fast bouquet making starts with harvest. We load the harvest vehicles up with buckets and make a game plan based on orders. If we know we have 65 cases of bouquets to make, then we know we need to harvest about 60-65 buckets of flowers. It is almost a 1:1 ratio for us because we end up bunching for florists and/or pulling wedding flowers from these buckets also. This includes lilies and pretty much all other crops, although some things are counted separately (seasonal bunches for grocers - zinnias, celosia; and some florist crops like dusty miller or lisianthus). We tell our employees that they are the first line of defense against bad product when they are out in the field. If a stem is too bent, too short, or the flower already damaged, they know to leave it in the field. There is no sense in an unusable flower going through the harvesting process just to get thrown in the compost later. We don’t usually cut anything that is less than 12”, but we are optimally going for at least 18”. When harvesting, we line up the stems at the bottom in our arms so as not to create a tangled mess when they are moved in and out of the bucket. We carry as much as we can without making the stems all crazy, then we gather everyone else’s bunches on our way back to the buckets in the vehicle to decrease steps taken.

“Cut & come again” flowers such as zinnias get deadheaded if not being harvested to regenerate new growth, but we try not to spend too much extra time in the field doing this. We may deadhead marigolds or ageratum if the first bloom is too short, although we have started to pinch these at planting so we can skip that step. This pinching back method (whether at planting, or when plants are about 6”) works for spike celosia as well, and I know other growers who pinch dianthus, amaranth, cosmos, and others.

With most flowers grown outside, we strip the leaves in the field so the stems are ready to make into bouquets. Some varieties, however, are simply cut in the field and processed when we get them to the barn. We let spike celosia, gomphrena, and marigolds bloom all the way out and then we cut the whole plant down, putting it into the bucket and processing up in the barn. Other things that get processed in the barn from the field are amaranth recuts, ornamental peppers, pumpkin on a stick, and Gomphocarpus ‘Oscar’. We do not strip dianthus, ammi, cornflower, scabiosa, and sometimes larkspur.

Below: The author and Gomphocarpus ‘Oscar’, which is one of the varieties that is not stripped in the field, but instead taken to the barn for processing. Photos courtesy of Sunny Meadows.

Greenhouse flowers are brought up to the barn to be stripped of leaves and bunched — that way we aren’t leaving debris in the greenhouse walkways. We have tried different methods and have found it’s most efficient for us to do all processing up in the barn. That gets flowers (and humans) out of the sun, and allows us to finish cutting and be able to stop for lunch at 12:30. If necessary, we send a partial crew out to the field after lunch while some of us start processing flowers. We bunch everything we need for florists first, and then use the rest of the flowers harvested for bouquets. This means that there may not be any of a particular florist crop (lisianthus, stock, snaps, or white dahlias, etc.) in a bouquet unless they were either graded out from florist bunching or were extras.

For quick bouquet making, preparation work is very important. We make sure all the flowers are stripped and ready to go, buckets filled, sleeves stickered, etc. Large flowers such as LA lilies and sunflowers stay in their buckets on the left side of the table where the bouquet-making begins. Then we set stacks of flowers on the table, out of water, blooms at the top. We try not to have more than seven items in a bouquet; otherwise it gets too cluttered on the table. We lay out the flowers so we will end up with a nice mix of focal and filler flowers and sometimes foliage. Once everything is ready, we make bouquets assembly-line fashion, working our way from left to right down the table, ending at the bouquet chopper.

We make our hand-tied bouquets starting in the center, and working outward. It is important for all the flowers to be visible from the top since that is how the customer will be viewing them, especially if there is a sleeve on the product. We don’t want it be “roundy-moundy,” though, so there is a fine balance to maintain. We hold the flowers as loosely and as low on the stems as we can, almost as if they would fall out of the hand, to ensure a bouquet has enough fluff. Think about the shape of the sleeve, how it flares out at the top. You want to create that same cone shape with the stems criss-crossed at the bottom rather than straight up and down. If there are any shorter flowers or foliage (dusty miller for example), they are typically put into the bouquets last on the outside of the bouquet so they don’t get lost. Accomplishing the “fluff” is the most difficult thing for people and takes some practice. You can have the same flowers look totally different if they are held at the top of their necks and packed in densely, which is people’s first instinct when handling flowers. Don’t be afraid to loosen up!

If you are dealing with something big or branching, we put those at the beginning of the table so we can work other flowers into them. Work your way down the table, adding stems to the bouquet as you go. We don’t actively turn the bouquet in the hand, but instead try to just place stems in the hand in different spots. As you get more coordinated, you can pick up more than one stem at a time. We grab 3-5 cosmos at once, use our fingers to splay them out, and then place in the bouquet trying to get onto three sides. Sounds like some crazy sleight-of-hand tricks, but it really does work!

Below, the final product: Sleeved bouquets are ready to be loaded for delivery to supermarkets. To watch a timelapse video of a bouquet session at Sunny Meadows Flower Farm, check out https://dl.dropboxusercontent.com/u/87435585/IMG_6453.MOV.

Our bouquets are typically one lily and 15-20 stems. Working in odd numbers is not really a rule we adhere to, although we will put two of something together rather than on opposite sides — no antennae, please! An example of a bouquet in the summer would be: 1 LA lily, 2 sunflowers, 3 zinnias, 3 spike celosia, 1 branchy piece of gomphrena, 3 dianthus, 2 stems geranium. Really, it differs every day and in every bouquet; we just want it to feel like a $15 bouquet. That is what the grocery stores charge. If there is something we have a ton of, we will make a requirement like 5 dianthus in every bouquet this time, or use 3 sunflowers to help fill space, zinnias on your table at all times, etc.

At the end of each table is a guillotine chopper that cuts the whole bouquet at once. They get banded with a #32 rubber band and set on a shelf, and then the bouquet makers go back to the beginning of the table to start all over again. We have another employee sleeve the bouquets, stacking them 3 and 2, placing the whole lot of 5 bouquets into the final bucket at one time. The person who is sleeving is also expediting the whole bouquet making process, so she has to be on her toes. She fills the bouquet makers’ tables, dumps buckets when we are finished with them to decrease clean up time, stocks rubber bands, switches compost bins, etc. She also loads flowers onto the cart and alerts us when we are getting near the end, in case there is anything specific that we need to use up.

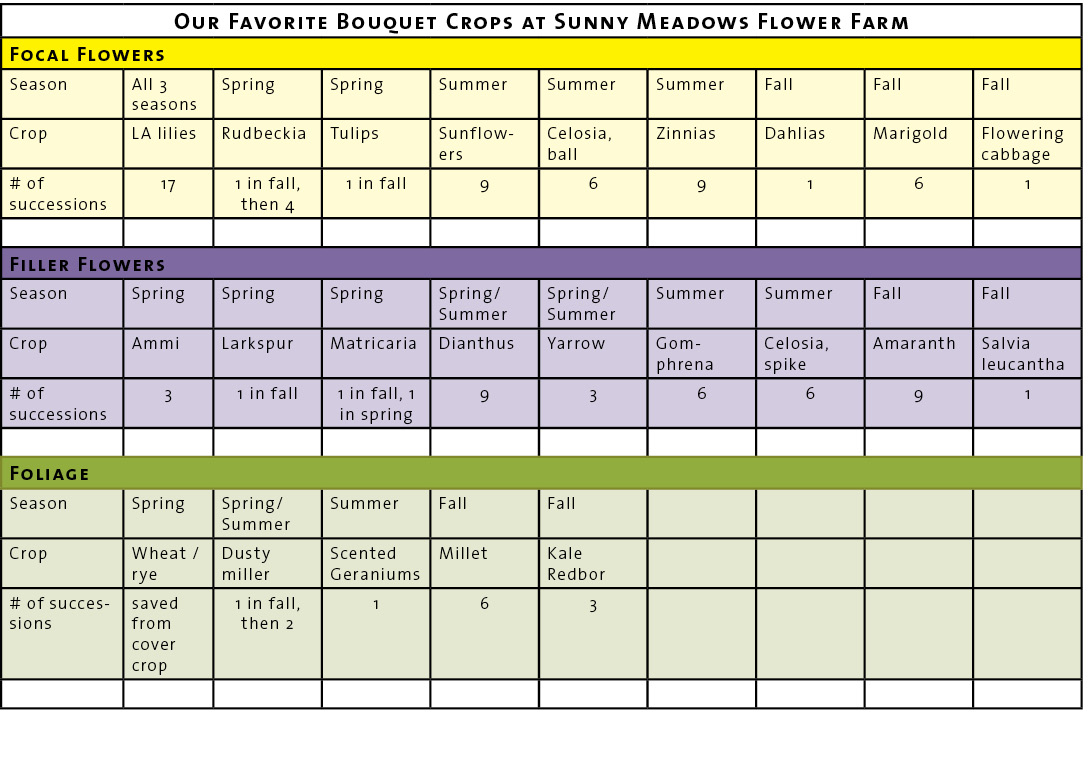

Our bouquets always have a base of 1 LA lily, so we plant prechilled lilies every 2-3 weeks from week 51 to week 33, to ensure harvest from Easter to Thanksgiving. We also plant enough successions and have crops blooming at different times to ensure we will have bouquet flowers throughout the season. Here is a chart with some of our favorites and the number of times we succession plant them throughout the season.

The good thing about bouquets is that they can absorb whatever is available. Sometimes there may be only 4-5 different crops depending on the time of season, but they are still beautiful.

For success with bouquets, get systems in place and then treat every bouquet-making session like a race. Crank up the volume on whatever music motivates you, and time yourself to see how fast you can go. It will be fun, I promise!

Below: Gretel harvesting celosia ‘Sunday Orange.

Gretel and Steve Adams own Sunny Meadows Flower Farm in Columbus, OH. Contact them directly to schedule their consultation services which can be tailored to fit your business or personal flower farming needs at [email protected].

Here's a system to track all those details

Here's a system to track all those details

For most established growers, the easiest place to start selling flowers will be mixed bouquets and single stem/small bunch retail sales. These are the flowers you can sell to your existing customers and they are easy to incorporate into farmers market, CSA, and grocery sales. But there are lots of other outlets out there, including florists, weddings and events, business subscriptions, value added products, and wholesalers.

For most established growers, the easiest place to start selling flowers will be mixed bouquets and single stem/small bunch retail sales. These are the flowers you can sell to your existing customers and they are easy to incorporate into farmers market, CSA, and grocery sales. But there are lots of other outlets out there, including florists, weddings and events, business subscriptions, value added products, and wholesalers.

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

Something we often get asked about at conferences is what it’s like to manage a crew. First off, bringing on other people was one of the best decisions we ever made. People are an investment, so it takes time and money to make it work, but all of that is worth it if it helps accomplish your goals for the farm and also helps give you more personal time back.

Something we often get asked about at conferences is what it’s like to manage a crew. First off, bringing on other people was one of the best decisions we ever made. People are an investment, so it takes time and money to make it work, but all of that is worth it if it helps accomplish your goals for the farm and also helps give you more personal time back.

This month’s submission is from Dogpatch Urban Gardens in Iowa and it’s a simple one – a grabber being used to reach Tomahooks obviating the need for a ladder. It’s quite possible that many of you have already thought of this, but I had never seen this before. I love the idea and I don’t even use hooks…but I might after seeing this.

This month’s submission is from Dogpatch Urban Gardens in Iowa and it’s a simple one – a grabber being used to reach Tomahooks obviating the need for a ladder. It’s quite possible that many of you have already thought of this, but I had never seen this before. I love the idea and I don’t even use hooks…but I might after seeing this.

Like all of you, I’m always trying to make little improvements around the farm, and I’m never finding enough time to try all of my ideas. Last year I had the opportunity to rebuild the packing area at Cully Neighborhood Farm (CNF) and to also build three prototype pieces of furniture for a new packing shed at the North Willamette Research and Education Center (NWREC) for their small demonstration farm and to try out some of my ideas.

Like all of you, I’m always trying to make little improvements around the farm, and I’m never finding enough time to try all of my ideas. Last year I had the opportunity to rebuild the packing area at Cully Neighborhood Farm (CNF) and to also build three prototype pieces of furniture for a new packing shed at the North Willamette Research and Education Center (NWREC) for their small demonstration farm and to try out some of my ideas.

We regularly harvest into a half dozen containers on our farm. Bulb crates, flip-top crates, storage crates, pallet bins, five gallon buckets, and waxed boxes. Our new favorite receptacle, though, is vastly more ergonomic and hands-free, and has changed the way we pick several crops, making it faster and more efficient and enjoyable.

We regularly harvest into a half dozen containers on our farm. Bulb crates, flip-top crates, storage crates, pallet bins, five gallon buckets, and waxed boxes. Our new favorite receptacle, though, is vastly more ergonomic and hands-free, and has changed the way we pick several crops, making it faster and more efficient and enjoyable.