What we learned from our SARE grant

Broccoli and cauliflower are fall staples on diversified produce operations like ours. Historically, they thrive in our northeastern region and provide heft, visual interest, and diversity to our direct market and CSA boxes.

But in recent years, growing heading fall brassicas feels like gambling. Hot summers stress seedlings. Autumn rolls in with waves of endless rain. Surges of Alternaria and black rot, with sporadic mildews and secondary head rots trash the plants. These wet fall conditions raise disease pressure while reducing spraying opportunities and efficacy.

At the same time, mild temperatures and later frosts encourage higher levels of insect pressure. Flea beetles linger here into October, while intermittent Swede midge flights drop in. For organic operators, row covers help produce unblemished heads, yet these covers simultaneously trap humidity on foliage, increase labor costs, and add hassle to fungicide applications.

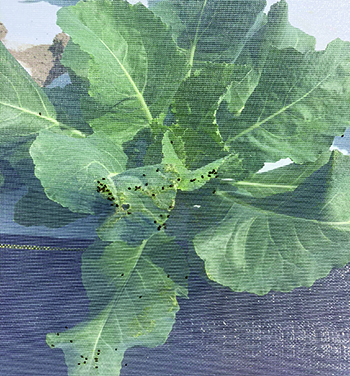

Flea beetles through netting. The flea beetles could not enter the netting, but did immediately begin feeding when leaves touched the edge of the net. Disease later started from these feeding points.

Flea beetles through netting. The flea beetles could not enter the netting, but did immediately begin feeding when leaves touched the edge of the net. Disease later started from these feeding points.

At our main market, we are the only grower supplying consistent late season cole crops (and we only do this because our CSA customers rank broccoli and cauliflower among their “must haves”). Our cost to produce these fall brassicas has skyrocketed since 2016, turning them from marginally breaking even into our biggest loss leaders.

What we wanted to know

Before we cut such fan favorites from our mix, we wanted to see if we were doing absolutely everything we could to produce them, and what impact such maximalist production effort would have on our net returns. We applied for a SARE farmer grant in 2021 to assess if the economics of our previously effective management strategies remained valid for organic fall brassica production as weather worsens.

Just a wee bit of funk. This is one of the healthier looking plants from our alternaria apocalyse zone. Normally, we would have terminated this planting to remove inoculum, but it was interesting to watch it progress and fester over the weeks (ick).

Just a wee bit of funk. This is one of the healthier looking plants from our alternaria apocalyse zone. Normally, we would have terminated this planting to remove inoculum, but it was interesting to watch it progress and fester over the weeks (ick).

What effort is worth putting into their disease management? Should we kill ourselves to get out and spray after every single storm? Do any cultural controls better support our spray regimen and make economic sense for these crops? Or is it more cost effective to use less intense management and accept some level of cosmetic damage, or even stop growing fall brassicas?

Our cropping conditions

We have well-drained but heavy silt loam on the escarpment in central New York. This creates high winds, extreme storms, and heavy nightly dews, which combine to make us rich in weird pests and foliar diseases. Half our production area rotates into cover crops or fallow each year, and the other half (6.5 certified organic acres in 2022) produces for CSA, farmers market, and small wholesale accounts. We usually have two full-time farmers and two seasonal staff, and our extended net labor costs here in NY run in the $20 to $25/hour range. Thus, higher labor operations like managing row covers and spraying may reduce disease load, but might not be profitable for some crops due to staffing costs.

We prepare all fields by incorporating cover crops, chisel plowing, and tilling in 1,500 to 2,000 pounds/acre of Kreher’s 5-4-3 pelleted composted chicken manure. Large brassicas are water wheel transplanted into 4’ white plastic mulch. Small brassica direct-seeded fields are bed formed prior to tillage, occulated under plastic tarps for three to eight weeks, and seeded with a single row Jang.

A little alternaria cauliflower in our earliest trial showing alternaria symptoms. Interestingly, most of the plants produced nice one pound heads (variety Bermeo) from this field, despite having heavy foliar issues. All photos courtesy of the author.

A little alternaria cauliflower in our earliest trial showing alternaria symptoms. Interestingly, most of the plants produced nice one pound heads (variety Bermeo) from this field, despite having heavy foliar issues. All photos courtesy of the author.

Given our more extreme growing and labor conditions, our hope is this trial would guide our farm and others to better assess the net profitability of fall cole crops in the years ahead as labor costs rise and growing conditions become more intense.

What we tested

We trialed seven cultural disease management strategies across three levels of fungicide application frequency. (Was this too many variables—you betcha! More on that next month.) Cultural controls included:

- Three exclusion methods: row cover, Proteknet, and no cover

- Two crop spacings: normal and wide

- Bare soil versus landscape fabric in aisles

- The spray levels tested were high (weekly preventative applications), moderate or “normal” (applications at two-week intervals), and low (zero to one applications). We tracked input costs, time and labor expenses, plant health and pest/disease pressure, and final marketable yields for each treatment.

- In the decade before this trial, we had already implemented the basic practices to minimize disease:

- We use long crop rotations to break disease cycles; started and then stopped using brassica cover crops; manage soil fertility; start with reputable seed; use heat treated seed; and trial every disease resistant variety available in the US!

- We only use healthy, vigorous seedlings. We even plant extra greenhouse successions of brassicas just to have spare rounds of seedlings for when weather might force planting delays.

- We strive for good field sanitation and rapid incorporation of old plantings. We have strict harvest workflow to pick from healthy fields before touching older plantings.

- We use wider spacing between rows and in-row (for example, we used to grow broccoli at three rows per bed with 12 to 15” in-row spacing, but switched to two rows per bed with 14” to 19” in-row). Our 2022 trial did test even wider spacing but additional spreading out showed no further positive economic impact.

Results- do organic fungicides even work?

The kicker of this trial is that nothing we sprayed, regardless of cultural practices, controlled Alternaria. (No other diseases had a major outbreak, however.)

Installing zone 1 in the trial field in a matrix of nine spray zones over seven cultural practices.

Installing zone 1 in the trial field in a matrix of nine spray zones over seven cultural practices.

We rotate fungicides to minimize resistance and because we have not seen strong efficacy from anything in the past. We used Howler, OSO, Carb-O-Nator, and Cueva from planting until harvest began (Zones 1 and 3), the Alternaria apocalypse wiped out the crop (Zone 2), or the crop was mature enough control was no longer necessary (Zone 4). Rather than assessing individual product efficacy, we assessed the impact of our frequency of application. (This was a mistake, as it further increased our number of variables!) For 2023, we switched our fungicide lineup to mostly use OSO again with a different copper formulation in Badge, based on Cornell Cooperative Extension’s Ethan Grundberg and Teresa Rusinek’s trial, which is available at: tinyurl.com/2urypr56.

Our data showed that spraying more than our normal two-week interval did not pay off with higher yields. Net income was slightly better actually the less we sprayed, thus answering our question—is it worth hammering crops with more frequent spray applications to reduce disease—in the negative. For direct seeded brassicas, data suggests stopping fungicide applications entirely.

However, we were pleasantly surprised at how well our pesticide applications controlled flea beetles on the uncovered zones in some of the later plantings. Rotating between Entrust and Evergreen Pyrethrum produced effective control over time, despite horrifying high initial pressure and damage.

To row cover or not (or get fancy with netting)?

Row cover has been a staple on our operation due to high flea beetle and Swede midge populations. Yet covers trap humidity to create perfect disease pit conditions. On our windy site, covers also abrade plants and open wounds for potential pathogen entry, and never last more than one or two uses.

We wanted to assess if row covers are still worth the drawbacks; if Proteknet’s high cost is offset by its easier scouting, spraying, and airflow; or if not using covers at all is a viable option (since it has been a decade since we dared grow brassicas without them).

We normally use 22’ wide Novagryl row cover spanning three beds over hoops, and struggled to fit the narrower Proteknet into our system. The 83” width did not quite cover one hooped bed, but the 10’ wide was overkill and too expensive. Our large framed plants quickly hit the netting fabric, and its wider holes allowed pests to stick all sorts of eating and egg laying proboscises through the mesh.

Humidity under row cover. Our site has heavy dews most days, with added moisture concentrating and lingering on the underside of any row covers.

Humidity under row cover. Our site has heavy dews most days, with added moisture concentrating and lingering on the underside of any row covers.

On a cost basis, for most zones the more expensive netting did not pay for itself relative to row cover, even factoring in that row cover is only used once and the netting many times. Scouting and spraying through the net was faster, but installation time costs were higher. There was an exception as direct seeded brassicas did have higher net yield and income under the more ventilated Proteknet.

This is an example of how netting can abrade and create room for pathogen entry on the leaves once they touch it.

This is an example of how netting can abrade and create room for pathogen entry on the leaves once they touch it.

Statistically, we did not see a huge efficacy difference between the three cover options in terms of disease reduction. But surprisingly, plantings without row cover had greater net yield per unit (but not net income per unit) and were more cost effective than we thought. It was significantly faster to plant, cultivate, and spray on iterations with no row cover or netting (duh!). Since so much of our variable cost comes from labor, saving time by not having to deal with moving anything did offset the lower yields of uncovered plantings.

Our conclusion across the pest cover trials was:

- Our row cover status quo remains the best middle ground option, but we should remove row covers three weeks earlier to capture some of the labor savings of uncovered plantings.

- In a time crunch, low pest, or wet year, we can forgo covers if we adjust our spray program. The plants look ugly for a while, but if they survive, they do produce.

- In direct seeded small brassicas, we can use netting as it does marginally increase yield.

Landscape fabric or bare ground?

We planted our large brassicas on white plastic, but in some zones we additionally used 4’ landscape fabric on the aisles, with the idea that it would further reduce splash and moisture from the ground. Landscape fabric surprisingly became the most statistically significant variable of the trial. Even considering that we used plastic directly under all transplanted crops and nothing was grown on bare ground, crops grown on beds that abutted landscape fabric aisles had higher net yields and net income. The fabric made for clean, accessible walkways, faster spray application, and easier harvest.

Row Cover vs Netting. A comparison of the Proteknet (right) and row cover (left) in a zone with landscape fabric covered aisles. (Yes, we use a lot of bags- we are one ridge over from a wind farm and hate chasing loose covers!)

Row Cover vs Netting. A comparison of the Proteknet (right) and row cover (left) in a zone with landscape fabric covered aisles. (Yes, we use a lot of bags- we are one ridge over from a wind farm and hate chasing loose covers!)

At the highest level of disease pressure, landscape fabric was the difference between getting some yield and nothing. In our Alternaria apocalypse trial field, landscape fabric correlated so strongly with higher yields and profitability that it altered the statistical significance of landscape fabric across all four trial fields. In a wet year with high disease pressure, it makes economic sense to prioritize using fabric.

Despite its net profitability, we despise the hassle of dealing with landscape fabric at larger scales of over a half-acre. While we continue to use it in limited situations, we want to assess how a straw or hay mulch would compare in this application (assuming we can keep the slugs at bay!).

Conclusions

Because we are rusty at science, we anticipated big, easy to interpret results to come out of this trial. And we did see and start making some systemic changes based on our SARE experience—but just not in the areas we were running trials on! Our biggest direct takeaways were:

- Our current operating practices are on target (and possibly overkill). Our farm just has challenging fall brassica cropping conditions.

- The disease pressure zones on our dewy farm are when plants touch ANYTHING—each other, hoops, row cover, a weed, netting, etc. Every touch point has potential to become pathogenic.

- The most profitable net yield/unit comes from using the least number of labor-intensive supplies (duh!). However, not all markets will accept the aesthetics of crops produced this way in our system and location.

- There are infinite variables in farming, and it is hard to assess in a single season what works. For example, did our fungicide regimen keep the non-Alternaria diseases down, or were we lucky? We need to re-run portions of this trial only using the most effective fungicide(s), and not a mix.

- Our biggest challenge with these crops in this seasonal slot is becoming more philosophical—to what extent do we need to keep customers happy by producing these vegetables and how perfect must they look? And with increasingly challenging fall weather, how do we weigh the value of organic production versus conventional production/keeping our sanity?

Between all the variables and the intense time and profit measurements, we found multiple paths forward that need more examination. Next month we will dig into what we learned about setting up a SARE farmer trial on the ground, plant torture experiments, the deep philosophical debates this trial kicked off, and some of our harder lessons!

This material is based upon work supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, through the Northeast Sustainable Agriculture Research and Education program under subaward number FNE22-030.

Maryellen Sheehan farms with her husband at Hartwood Farm in central NY, after growing in the Hudson Valley, NH, and MA. They raise vegetables of all kinds, previously mostly for CSA but now a growing wholesale market and their local community, but secretly just want to grow trees.