By Ellen Polishuk

I was born loving plants. Instead of animal pets I had plant pets in my room. One of the best gifts I ever got as a kid was a three-tiered white plastic plant stand. How’s that for a strange kid? My relationship with growing food crops began when at age nine I got a tiny, heavy clay soil garden plot at the local community garden in Reston, VA.

My first paid summer job was working as trail crew at Great Falls National Park—uniform, boots, hat, and tin drinking cup hanging from my belt. I loved being outside, and this seemed like a natural fit. Frankly, it was boring, as we picked up a lot trash and painted trash cans. At age 16, I got a job working for Cox Farms. I worked part-time at their farm store in the Kmart shopping center, and part-time on the farm.

The farm was on an island in the Potomac River, and was staffed by 20-somethings who lived in a house across the river from the farm. We had to row to get to work! I did a lot of hoeing in the broiling sun, transplanting on a machine, and picked a lot of summer squash. It was awesome.

Potomac Vegetable Farms

Next, my Mom encouraged me to attend Horticulture Night at the local community college. I gave her an attitude, but went anyway. Various horticulture professionals talked about their jobs, which sounded uninspiring. But one speaker was Hiu Newcomb of Potomac Vegetable Farms (PVF).

Her talk enraptured me. She conjured up a vision of good hard work that yielded a valuable product (food) while developing a connection to the Earth. I was all in, and asked for a job at the event. She didn’t seem too excited about the prospect, but hired me anyway later that spring, because as a commuter worker I wasn’t a high-risk hire.

I worked that first PVF summer and got paid $2.70 an hour. It was grueling work. I liked it but by the end felt the pay was not commensurate with the energy input. So I vowed to make some real money the next summer, like all my friends did. By this point, I was attending the University of Virginia, going for an English degree. The summer after my first year, I worked at the CIA, as in the Central Intelligence Agency, not the Culinary Institute of America!

My step-father was a career analyst there, and they hired children of employees because they basically already knew your security background. I wore dresses and heels all summer, and basically accomplished very little. I was supremely bored, but made $10 an hour. After that summer, I vowed never to work just for the money. I wanted to go back to PVF and find out more about this farming thing. I also decided to transfer to Virginia Tech to pursue a degree in agriculture.

In total I worked at PVF four different seasons before graduating from VT in 1986 with a horticulture degree. I loved the work, I loved my workmates and bosses, I gained many skills and responsibilities over those years. I could drive an International Harvester B cultivator, disk a field with an Oliver 770, drive a three-on-the-tree Ford F150 to the farmers market and back, do the market by myself, harvest (at my best in a race) 18 half bushel baskets of tomatoes that were grown on the ground with no trellis in an hour, etc. Not too shabby for a kid from the ‘burbs, with no farmers in the family!

40,000 acres of tomatoes in California

Off to California with my boyfriend I went, so he could go to UC Davis, and I could get away from the East Coast. I hadn’t been west of West Virginia at this point and needed to see some new places. I lived in Davis for four years and worked for Harris Moran Seed Company as a plant breeder’s assistant at a research farm just outside of town.

The pay was decent, I got health insurance (and thus lots of dental work!), learned a ton about plant breeding, but most importantly about conventional big-time agriculture. Davis is in the Central Valley of California, and my main crop was processing tomatoes. I hadn’t even known such a beast existed before. We did variety trials on a farm four hours south that grew 40,000 acres of processing tomatoes. This was about as different to my experience at PVF as possible.

While my education about conventional ag progressed, I volunteered extensively with the Committee for Sustainable Agriculture, California’s main forum for organic farmers and supporters. I became a fervent advocate for the sustainable ag movement, helping found an event called the Hoes Down Festival, and culminating in being the head organizer of the EcoFarm conference at Asilomar in 1990.

Then my time in California came to a close and I headed back to Virginia to become a farmer. While I enjoyed my time there, I wanted to be back on the East Coast where organics were still in the early stages. I wanted to be at the beginning of the movement, rather than in the center of the wave.

So I settled in Charlottesville, VA, for love reasons, and noodled how to become a farmer again. After some pencil pushing, and assessing my resources, it became immediately clear that I couldn’t just go out and buy a place and start my farm. So, instead I joined forces with someone to help him grow his farm to a new scale.

We started the first CSA in Virginia in 1991, called Circle Harvest. There were about 10 CSA farms in the US at that time, and I visited Genesis Farm in New Jersey, and another in New York to try to understand how they worked. My farm partner and I cold-called people, held open meetings in churches, and finally sold 40 shares.

It turned out we were not great partners for each other, the land was poor, we had few tools, and it was just plain too much work. At this point, I headed back up to PVF to cry to Hana Newcomb that I had hit a wall, there was just NO WAY I could be a farmer! I had no money, no land, no family money, nothing to go on. Maybe I should just go back to school and be a lawyer or CPA or something? She calmly listened, as we picked green beans, and then said “well, we have that property out in Loudoun County, maybe you should farm that for us?”

And so that’s what I did.

Potomac Vegetable Farms part two

I began what turned out to be a 25-year stint at Potomac Vegetable Farms in 1992. The land in Loudoun County was to be transitioned from year after year of no-till sweet corn grown with herbicide and chemical fertilizer to a diversified organic vegetable operation. There were about 50 acres tillable, and two tricycle front-end Oliver gas tractors, a small field shed, no fuel tanks, two disks, a 14’ bushhog, and a 40x60 barn full of manure (yep about 4-5 feet high!), trash and recyclables (collecting until the year when recycling would ever begin out there!). As I think of that now, I’m despondent with worry and warning, but at the time I was super gung-ho to get going, scared but determined. The farm built me a house, where I lived after 1993. How’s that for a welcome gift?

My crop mandate was to figure out (soon but not immediately) how to grow 15 acres of organic sweet corn, and to begin a small market garden on one acre that had been free of chemicals for a number of years. The garden part wasn’t so bad, except for the deer! But the sweet corn was a momentous task.

The path started to become clear after a couple of years of searching, asking, and listening. At a winter organic farm conference in Texas, I heard a sugarcane grower speak of a consultant in the Midwest who helped him turn his farm from all chemicals toward a more biological approach. So I called Edwin Blosser at Midwest Bio-Systems to ask for help. After he looked at my soil tests, he said this: “I can sell you something in a bucket, I can sell you something in a bag, but what you really need is to learn how to make some good compost.” Since when does someone convince you NOT to buy their product?

Edwin pointed me toward George Leidig of Autrusa Compost and told me to get some education. George was selling Sandberger compost turners from Austria, and bringing the compost guru Leubke family over to the US to teach the science and technology of composting. I signed up for day one of a four-day compost class. Day one was for those wanting to dip their toes and test the water. The class was held in the middle of Amish country in Bird-in-Hand, PA. After class ended, my head was exploding, and I felt the call to become a compost maker.

I drove back three hours to have a meeting with Hana and her mother Hiu, to explain what I had learned, and to see if I could enroll them in this tremendous new project. It was going to cost around $50,000 to get the whole thing set up: turning machine, compost pad, skid loader to construct the piles, and some testing equipment and compost covers. Hana asked me “is this the cutting edge?” And I said “yes.” So they gave me the thumbs up. And I went back to Lancaster County the next morning to consume Days two, three, and four of the class.

Making compost

Our first turning machine, arriving in 1994, was a prototype self-propelled diesel model, hand made by an Amish man who technically couldn’t drive it because it had rubber wheels. It was a bear, and cool to operate. George Leidig consulted with us the whole way through the process of getting the pad installed, and came and worked with me to construct the very first piles. It was thrilling.

The key features of the Leubke method (also known as Controlled Microbial Composting or CMC composting) is that the piles have some clay/soil as an ingredient (to help form a more stable humus product), are monitored daily for temperature and CO2 levels, are turned with a specially designed and patented turning drum, and are always covered with a breathable spun polyester fabric much like Gore-Tex. The resulting compost is gorgeous, black, life-giving fertilizer, all done in 8-10 weeks. (PVF still makes compost this way now.)

The fertility program was to make and spread as much compost as we could manage and grow winter cover crops religiously. We didn’t add any other soil amendments. The results were good. I finally figured out how to grow some decent organic sweet corn. But it turned out to be unprofitable. So gradually we grew less and less, and just bought the corn from the Eastern Shore of Maryland to keep our roadside stands happy.

A new chapter

In 1995 there was a tremendous spring storm with hail and high winds. As I stood in my house and listened to the hail hit all four sides at the same time, I freaked out about how bad the crops were going to look the next morning. It was bad, but not unrecoverable. But, that event sparked a new topic—I decided that I needed to worry about and invest in something more lasting than a tomato plant, and thus decided that I wanted a child.

As luck would have it, a farmer we knew was temporarily farmless, and I welcomed Heinz Thomet (now of Next Step Produce in Maryland) to my home. We fixed him up a little apartment inside the house, gave him desk space in the rec room, and he moved in the winter of 1995. My son Aaron was born in June of 1996.

Heinz held the fort, and more, while I figured out how to nurse and mother, and keep the crew working. During the two years that Heinz was with us, he taught me so many things. He’d grown up on a farm in Switzerland and had developed Genesis Farm in New Jersey into a thriving gorgeous organic CSA farm. He was the real deal.

He taught me how to see the farm from the 35,000-foot perspective, how to better align the row direction with the contour, how to take care of equipment, keep things tidy, design more ergonomic systems, and generally how to be a much better farmer. He also taught me how to cook amazing vegan food, take care of orchids, and count in German.

We made more important equipment upgrades during that time: a Barschi root digger and brush hoe, and an Imants spader. Heinz was fearless at conquering messes, and took the lead on reclaiming the big barn and shop so that we could actually make use of them. What a time that was, all that work and learning, with my little boy growing up in the midst. (Aaron went to full-time daycare so that I could manage the farm.)

The market garden prospered. The farmers markets and CSA (started in 2000) had voracious appetites, so we kept growing more and more. In 2003, I was lucky enough to be accepted into a grant funded program called the Experienced Farmers Network, a group of 14 farmers in the Southeast that had ten years under their belts growing produce. Over the course of the next 18 months, we spent hours and hours, days and days, email after email, learning and discussing with each other how we farmed. It was a tremendous process that resulted in life-long friendships, minor production adjustments, and one major mind shift.

That shift occurred when I visited one farmer participant solo. In the course of our time together, I asked them how much money they actually netted from farming. Their answer surprised me greatly—it was more than double my salary! I decided then and there that I could and would try to double my salary.

The Game

I took that goal home with me, and with the blessings of my farm partners, created something we called The Game. I asked us to pretend (and I did all the bookkeeping) that I was farming the Loudoun location on my own—that the markets I attended were “mine,” that all the produce I sent to them was a wholesale “sale”, and that all the costs associated with Loudoun were “mine” to pay for. In fact, we were the same two farm location as always, one company, but I wanted to prove to myself that I could farm profitably, and to pay myself better in the process.

The results of The Game were that both farms produced record amounts of vegetables, record gross sales, and that I managed to double my salary in two years. My partners also increased their salaries to almost double as well.

How could this have happened?

My explanation is that we all worked harder, and smarter, were more ambitious, and more cost conscious. We had simply changed the parameters and goals of our work, and had upped our games across the board. We suspended The Game after a few years as I had proven my point, and the bookkeeping was onerous, and it had also created a little too much competitiveness amongst the farm families. But the lesson was a huge one for me, and one that I take into my teaching role currently.

Another thread of this story that deserves sharing, is the slow gentle persistence to make PVF a long-term business via changing the ownership structure. From its beginning PVF was a sole proprietorship of Hiu and Tony Newcomb. After Tony died in 1986, it was Hiu at the helm, but she knew she needed lots of help and ideas of others to keep the business prospering.

Her daughters Hana and Lani both took on more responsibilities, and the local Southern States truck driver was hired to take over farming the Loudoun property. It wasn’t until I was hired on full-time permanently in 1992, that Hiu and Hana seriously considered making PVF a group owned company. We all agreed that after a successful three-year courtship, we would figure out how to “get married” business-wise.

In the end, it took us much longer to make it all happen then we planned. We hired an accountant, who helped us turn PVF into an “S” corporation. (The farm company would own only tools, buildings, crops and equipment, but no land.) Then, the process of gifting shares began. On day one of PVF, Inc., Hiu owned all the shares, because she owned all the assets of the original business.

To avoid costly tax consequences to Hana and me, the process of ownership transferal went like this: Hiu would gift us $11,000 worth of shares each year (the max gift possible with no tax incurred), and Hana and I would earn newly created shares each year (while Hiu did not). After about five years of this paper game, we were all three equal owners of PVF Inc. How cool is that? From earning $2.40 an hour in 1981 to one third owner (approximate equity of $150,000) in 2008, what a good journey and a testament to forward thinking and generous acting people (Hana and Hiu!).

It all comes back to the soil

My agricultural path had a couple of other major events that permanently affected how I farmed. The first was meeting Gary Zimmer of Midwestern BioAg (MBA) in Wisconsin. Through my neighbor Rob Moutoux, I was invited to take part in a four-day soil fertility and fertilizer workshop at a farm in Lancaster County, Pennsylvania. John Kempf of Advancing Eco Agriculture was there too. My understanding of soil biology, chemistry and physics grew exponentially during a short period of time.

The main take away was really very simple: make sure your plants have enough nutrients available by adding those that are missing and enhancing biological activity as much as possible. I already had a good feeling for how to enhance biology through cover cropping, green manures and compost. But I was missing the piece about bringing nutrients onto the farm. We needed phosphorus, calcium and boron badly. So, I began buying Tennessee brown rock phosphate by the semi load, and getting a custom dry-blended, humate-coated annual crop fertilizer from MBA. We saw resulting increases in crop yield and crop health.

I’ve always been a conference fanatic, and perhaps my favorite conference was a tiny one held an hour from my farm called the Local Food Project Conference (no longer happening, but thanks to Pablo Elliot for doing such great ones!). In 2010, the Nordells from Beech Grove Farm in Pennsylvania, and the Martens of Lakeview Organic Grain in New York shared the stage for a whole day. Eric and Anne Nordell described in gory detail their rotation system, which you can read about at https://tinyurl.com/ybzyx85m.

My mind was officially blown, and home I went to adapt their idea to my farm. I ended up with what I call the Vacation Program. I describe it in a video available at https://tinyurl.com/yarud2ey. Basically, I divided the farm into two halves (made up from a varied collection of patches) and cropped one half in vegetables and the other half in soil building crops each season. The following year, the plan would switch. This program allowed each patch to have about 16-18 months of “vacation” out of every 24 months. This sure did give us production results!

As the years rolled by and the farm continued to succeed, my body’s aches and pains became more and more a limiting factor to my enjoyment of farming. I called out to the universe to send me someone to help me manage the farm and share more of the burden of the physical work. PVF entered into a three-year courtship with a young couple that did not turn into a marriage.

By 2016 I was ready to make my way out of farming without having found my replacement. I had already been doing some soils consulting, conference workshops, and had a two-year stint at the University of Maryland teaching sustainable ag to undergrads. We at PVF put our good work of setting up the farm corporation to the ultimate test – how to get divorced and still like each other! It all worked out quite smoothly and without hard feelings.

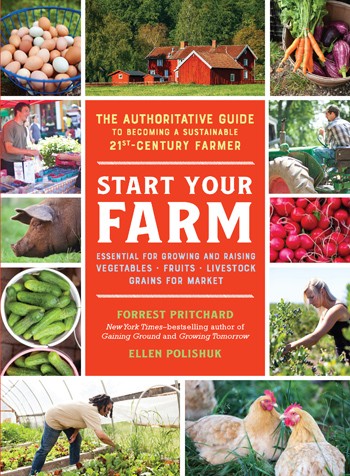

In December 2016, I sold my PVF shares back to Hiu Newcomb. Hana took over the management of the Loudoun farm. I moved across the Potomac River to Maryland so I could join my sweetie Dan. He and I bought a wonderful homestead on five acres a year ago and got married in May of 2018. Since leaving the farm, I’ve put all my energies into building my consulting and teaching business into a full time job. I co-wrote a book with Forrest Pritchard called Start Your Farm, which came out in September 2018.

My new life is going wonderfully. I enjoy writing, speaking, teaching and especially the one-on-one work I do with farmers around the country. It is really such a tremendous honor to be allowed to help people with their farm businesses. And I came up with this Farmer to Farmer Profile column, as a way to keep me visiting farms and learning more about production techniques and farm business strategies. I look forward to us all learning together to help make our farms more economically successful, biologically active, and full of joy.

More photos from this story are at tinyurl.com/ycbv3sqz.

Click here for an excerpt from Ellen’s new book, Start Your Farm: The Authoritative Guide to Becoming a Sustainable 21st Century Farmer, which appeared in the January 2019 GFM. Start Your Farm is available from Growing for Market for $19.95. As always, subscirbers get 20% off all books.

Ellen Polishuk just retired from growing 25 acres of ecoganic vegetables and other crops at Potomac Vegetable Farms in northern Virginia. She is now a full-time farm consultant, writer and teacher. For more info go to planttoprofit.com.

Julia Asherman appeared on my radar screen a number of years ago because she was a regular presence at the Southern Sustainable Agriculture Working Group conferences where I’ve spoken many times. Colleagues pointed her out to me as a person to watch because she was tough and smart and she was going to make something of herself as a farmer. We became conference buddies. So, when I had the good fortune to get invited to speak at the Georgia Organics Conference in Athens this winter, I knew right away I wanted to take that opportunity to visit Julia at her place, Rag & Frass Farm in Jeffersonville, Georgia.

Julia Asherman appeared on my radar screen a number of years ago because she was a regular presence at the Southern Sustainable Agriculture Working Group conferences where I’ve spoken many times. Colleagues pointed her out to me as a person to watch because she was tough and smart and she was going to make something of herself as a farmer. We became conference buddies. So, when I had the good fortune to get invited to speak at the Georgia Organics Conference in Athens this winter, I knew right away I wanted to take that opportunity to visit Julia at her place, Rag & Frass Farm in Jeffersonville, Georgia.

It’s a wondrous, if slow, drive from Asheville, NC northeast along the eastern edge of the Appalachian Mountains. That’s because it’s snowing pretty hard, making the roads both a little iffy, and strangely empty. School is cancelled, and the world sits still to see how much wet white stuff will land on this mid-March Monday. As I get closer to the farm, the roads are getting smaller and windier. Finally, I cross Tumbling Shoals Creek, and know that my destination must be near! The last narrow gravel road brings me to a picturesque view of a tidy small farm across the creek, dotted with fields and multiple plastic covered growing structures.

It’s a wondrous, if slow, drive from Asheville, NC northeast along the eastern edge of the Appalachian Mountains. That’s because it’s snowing pretty hard, making the roads both a little iffy, and strangely empty. School is cancelled, and the world sits still to see how much wet white stuff will land on this mid-March Monday. As I get closer to the farm, the roads are getting smaller and windier. Finally, I cross Tumbling Shoals Creek, and know that my destination must be near! The last narrow gravel road brings me to a picturesque view of a tidy small farm across the creek, dotted with fields and multiple plastic covered growing structures..png)

The impacts of climate chaos on Astarte Farm have forced us to look for solutions that provide increased long-term resilience in our soil systems, and biochar has shown good promise in moving us toward that goal. Biochar is a paradoxical substance. It is both an ancient agricultural practice developed thousands of years ago in the Amazonian Basin, and at the same time a relatively new approach to enhancing and stabilizing soil fertility.

The impacts of climate chaos on Astarte Farm have forced us to look for solutions that provide increased long-term resilience in our soil systems, and biochar has shown good promise in moving us toward that goal. Biochar is a paradoxical substance. It is both an ancient agricultural practice developed thousands of years ago in the Amazonian Basin, and at the same time a relatively new approach to enhancing and stabilizing soil fertility.

We at Four Winds Farm in Gardiner, New York have developed a no-till approach to farming that uses a lot of compost – 40 yards per acre. When we first developed our model 20 years ago, our market garden was small, only 1.5 acres, and we got our compost from an off-farm source. As we expanded, it made sense that we figure out a way of making our own compost.

We at Four Winds Farm in Gardiner, New York have developed a no-till approach to farming that uses a lot of compost – 40 yards per acre. When we first developed our model 20 years ago, our market garden was small, only 1.5 acres, and we got our compost from an off-farm source. As we expanded, it made sense that we figure out a way of making our own compost.

During the COVID era my usual travels have been curtailed. So, I got to thinking about what farms I had visited in the past that I knew pretty well, where a simple phone call could possibly stand-in for a proper on-farm interview and tour. First to my mind was Dripping Springs Garden, an oasis of natural and man-made beauty that is the life’s work of a good friend of mine, Mark Cain, and his farm partner, Michael Crane.

During the COVID era my usual travels have been curtailed. So, I got to thinking about what farms I had visited in the past that I knew pretty well, where a simple phone call could possibly stand-in for a proper on-farm interview and tour. First to my mind was Dripping Springs Garden, an oasis of natural and man-made beauty that is the life’s work of a good friend of mine, Mark Cain, and his farm partner, Michael Crane.

Farmer to Farmer Profile

Farmer to Farmer Profile

I made a trek out to Wisconsin in June. I’ve been lucky enough to visit this gorgeous state a few times, and I was glad to return. Wisconsin is the state with the second most organic acres in the country, behind California. It’s been an important crucible for the organic ag movement since the beginning. Out of the 177 of Chris Blanchard’s Farmer to Farmer podcasts, 21 featured Wisconsin-based businesses. From that list I chose two farms to visit and interview for this column.

I made a trek out to Wisconsin in June. I’ve been lucky enough to visit this gorgeous state a few times, and I was glad to return. Wisconsin is the state with the second most organic acres in the country, behind California. It’s been an important crucible for the organic ag movement since the beginning. Out of the 177 of Chris Blanchard’s Farmer to Farmer podcasts, 21 featured Wisconsin-based businesses. From that list I chose two farms to visit and interview for this column.

Farmer to Farmer Profile

Farmer to Farmer Profile

Blue House Farm is a two-location operation with both farms being leased, one from a family trust, and the other from a land trust. The “home” farm is 15 minutes away in Pescadero, which is where Ryan lives, and where the farms’ wash/pack facility stands, and where the market trucks leave from on any given day. It’s warmer there and much less foggy, and Ryan leases a little apple and pear orchard adjacent to the property.

Blue House Farm is a two-location operation with both farms being leased, one from a family trust, and the other from a land trust. The “home” farm is 15 minutes away in Pescadero, which is where Ryan lives, and where the farms’ wash/pack facility stands, and where the market trucks leave from on any given day. It’s warmer there and much less foggy, and Ryan leases a little apple and pear orchard adjacent to the property.

Getting to High Ground Organics means going through the belly of the beast of California’s agricultural sweet spot – the Central Coast. This is where high value crops are grown right to the property line, right next to towns and suburbs, cheek by jowl. The proximity to the Pacific Ocean mitigates the climate of this region so it’s never that hot and never that cold; they can grow and harvest strawberries from March to October.

Getting to High Ground Organics means going through the belly of the beast of California’s agricultural sweet spot – the Central Coast. This is where high value crops are grown right to the property line, right next to towns and suburbs, cheek by jowl. The proximity to the Pacific Ocean mitigates the climate of this region so it’s never that hot and never that cold; they can grow and harvest strawberries from March to October.