Buffalo Organics, our farm in East Aurora, New York, has been a CSA since 1997. About 75% of our sales are to our CSA, the rest to two farmers’ markets and the local natural food cooperative. Our basic philosophy is that shareholders come first, and excess production is sold elsewhere.

Our income, however, is inadequate and we are always seeking ways to earn more without working more. We try to work smart so we can have more time for our two young children.

We decided that we needed to increase our net income without significantly increasing the number of shareholders we serve. With that in mind, we added a fruit share option to our CSA last year. We expected that about 50 of our 130 shareholders would participate. Ninety families (69%) signed up. Shareholder response has been overwhelmingly positive. Many of those who did not have a fruit share indicated they would purchase one in 2002. In our first year, we added thousands of dollars to our net income while providing a valuable service for our members.

Here is how we proposed the idea to our shareholders in our 2001 brochure:

“We are excited to offer fruit this year! Those who want to purchase fresh picked; low-spray and organic fruit can sign up for a fruit share, *Strawberries, *raspberries *blueberries, cherries, apricots, plums, peaches, *apples, and pears will be purchased from Erie and Niagara County farmers. (The star indicates which fruit is certified organic. All other fruit is low spray and/or IPM managed.) The price for a fruit share is $200 ($10/wk.). Fruit will be distributed approximately 20 weeks beginning with strawberries in June.”

Prior to the season we were given general harvest dates and prices for the fruit from the growers. Both fruit growers delivered to our farm. The organic raspberries, strawberries, and blueberries were picked the day of distribution and delivered twice weekly before 1 p.m. The tree fruit was delivered weekly. To make the long drive worthwhile for the grower, we ordered with another local farmer. This insured that their truck would be full every week.

Distribution occurred at the farm and at two managed drop sites. At the farm the fruit was distributed from the containers it was packed in. Flats and crates were attractively placed on the floor or on a table. The fruit was clearly labeled by variety and what quantity to take. Those interested were told what the low-spray and IPM crops were treated with and when. We did not post this information. The fruit had its own section of the barn. Fruit was taken directly from the delivery trucks to where they would be given to shareholders. Fruit remaining after distribution and for shares later in the week was stored in a walk-in cooler. Very little labor was involved in handling the farm-distributed fruit.

The off-farm distributed fruit was another story. Fruit going to drop sites was bagged for each share. Early in the season when the fruit was in cartons, this was not a problem. When the tree fruit arrived, we started spending a lot of time bagging fruit. This was a mistake. Fruit was bruised due to excessive handling. Further damage occurred with packing the bags, loading the boxes and shipping. Labor was also expended which could be more profitably used elsewhere. Mid-season we started sending the fruit out bulk and providing a scale. Shareholders seemed happy with this arrangement. They did however, suggest we provide two scales. An additional benefit beyond the above-mentioned quality issue was that shareholders could now choose what varieties they wanted. We over packed to insure we would not run out. Leftovers were taken by the distribution manager or donated to charity.

Fruit quality was excellent from our growers. Many shareholders mentioned that it was the best fruit they ever tasted. Education was important. The organic raspberries and strawberries were untreated and despite being picked the morning of distribution they had a very short shelf life. We recommended that they be eaten within three days or frozen immediately.

We did have a problem with worms in the organic Macintoshes. One shareholder was so disgusted she stopped taking her fruit. Again, education was important. We explained in our newsletter that insect pressure was intense at the farm, perhaps due to the drought. The other organic apple varieties did not have this problem. We stopped ordering Macs. We asked the grower not to send us fruit with worms in the future. We want the highest quality fruit for our shareholders. Letting suppliers know what is acceptable ensures continued quality. We do not want our growers giving us lesser fruit because they know we will accept it.

The money end

The $200 price of the share was not derived from financial statements. We assumed $10 would be an amount people would be willing to pay a week for fruit. We then established that we wanted a 30% profit margin on the program.

We were figuring it out as we went. As we got into the tree fruit we realized that to maintain our target margin we would have to give out far too much fruit. Initially, we felt guilty taking high margins. With our local supermarkets charging more than us for inferior fruit, we quickly lost our apprehension. Shareholders were receiving good value and we were making money. Near the end of the season as I was dropping off the apples for distribution at the local food cooperative I noticed that they were selling apples for 35 cents a pound. The share for the week was six pounds for $10. $2.10 worth of apples for $10 was not math that was going to make shareholders happy. To get to our distribution site the shareholders had to walk through this big display of these inexpensive apples. We decided to compensate the shareholders by adding two quarts of organic apple nectar for the next two distributions and by extending the season an extra week. Our vegetable CSA program ran one week longer than the fruit share so providing a bonus fruit week was not a problem. They would get another allotment of apples and two gallons of custom pressed raw organic cider. The cider was special since in our area organic unpasteurized cider is not available. The shareholders ended the season happy with their cider and the program. Our margin ended up being 44% on sales of $17,400, returning a gross profit before labor of $7,656. Bagging the fruit took a non-paid working shareholder two hours a week for a total of 22 hours. When we shifted to distributing bulk, it took about 20 minutes to handle the fruit a week.

The fruit share is now an important component of our farm business. The prepaid shares provide operating income. The program provides profits for the farm. This season we suffered a severe drought with rain levels not seen since the dust bowl era in the 1930’s. Our yields were depressed and we lost significant farmers market income. Without the fruit share income we would not have been able to make our full pension contributions.

The fruit share is the first component of our strategy to increase our net income without significantly increasing the number of shareholders we service. We want to increase the dollar value of each share by capturing a greater percentage of their total food purchases. The more staples they can pick-up at the farm means less running around for them. We want to offer our shareholders the same high quality artisan food we enjoy. In most cases this food is not readily available elsewhere. We want to build shareholder loyalty by delivering what customers want. We feel that our long-term viability insists that we provide a service people need.

.png)

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

It’s not too late for online/preorder seedling sales, farmers market custom bags, and We Give a Share

It’s not too late for online/preorder seedling sales, farmers market custom bags, and We Give a Share

Farmer to Farmer Profile

Farmer to Farmer Profile

Why is the flower micro-farm best suited to a laser focus on one or two enterprises versus a balance of several? It is because of the long maturity of flower crops and the specific and conflicting demands of different types of flower enterprises. For example, some of the most common ways for farms to sell their flowers are at a farmers market, wholesale, from a flower stand/truck, a CSA, and weddings/events. These outlets can be compared on their need for similar types and quantities of flowers.

Why is the flower micro-farm best suited to a laser focus on one or two enterprises versus a balance of several? It is because of the long maturity of flower crops and the specific and conflicting demands of different types of flower enterprises. For example, some of the most common ways for farms to sell their flowers are at a farmers market, wholesale, from a flower stand/truck, a CSA, and weddings/events. These outlets can be compared on their need for similar types and quantities of flowers.

For most established growers, the easiest place to start selling flowers will be mixed bouquets and single stem/small bunch retail sales. These are the flowers you can sell to your existing customers and they are easy to incorporate into farmers market, CSA, and grocery sales. But there are lots of other outlets out there, including florists, weddings and events, business subscriptions, value added products, and wholesalers.

For most established growers, the easiest place to start selling flowers will be mixed bouquets and single stem/small bunch retail sales. These are the flowers you can sell to your existing customers and they are easy to incorporate into farmers market, CSA, and grocery sales. But there are lots of other outlets out there, including florists, weddings and events, business subscriptions, value added products, and wholesalers.

I made a trek out to Wisconsin in June. I’ve been lucky enough to visit this gorgeous state a few times, and I was glad to return. Wisconsin is the state with the second most organic acres in the country, behind California. It’s been an important crucible for the organic ag movement since the beginning. Out of the 177 of Chris Blanchard’s Farmer to Farmer podcasts, 21 featured Wisconsin-based businesses. From that list I chose two farms to visit and interview for this column.

I made a trek out to Wisconsin in June. I’ve been lucky enough to visit this gorgeous state a few times, and I was glad to return. Wisconsin is the state with the second most organic acres in the country, behind California. It’s been an important crucible for the organic ag movement since the beginning. Out of the 177 of Chris Blanchard’s Farmer to Farmer podcasts, 21 featured Wisconsin-based businesses. From that list I chose two farms to visit and interview for this column.

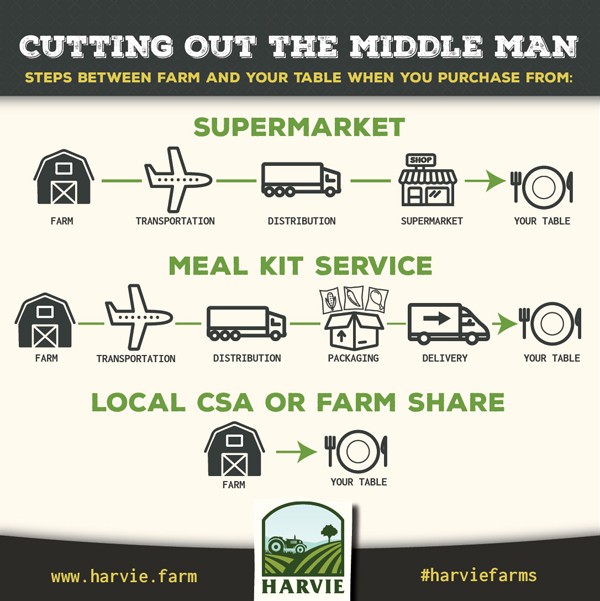

“CSA is dead” is a refrain I have heard from multiple farms in the past few years. I started to hear rumblings of a problem with the CSA model in 2014 through the CSA Farmer Discussion group that I manage on Facebook which brings together over 2,500 CSA farmers from all over the world. Farmers reported that they were having trouble attracting and retaining membership.

“CSA is dead” is a refrain I have heard from multiple farms in the past few years. I started to hear rumblings of a problem with the CSA model in 2014 through the CSA Farmer Discussion group that I manage on Facebook which brings together over 2,500 CSA farmers from all over the world. Farmers reported that they were having trouble attracting and retaining membership..jpg)

It’s an incredibly cool, clear and dry July day in Massachusetts as I make my way to Brookfield Farm. Dan has arranged for me to visit at 2PM on a Thursday so I can see this bustling CSA farm at distribution time. I arrive just before the appointed hour, and see the last details of the setup being handled by apprentice Ellen. Dan and Karen are bustling around the corner, checking that the room is ready for the deluge of customers to come.

It’s an incredibly cool, clear and dry July day in Massachusetts as I make my way to Brookfield Farm. Dan has arranged for me to visit at 2PM on a Thursday so I can see this bustling CSA farm at distribution time. I arrive just before the appointed hour, and see the last details of the setup being handled by apprentice Ellen. Dan and Karen are bustling around the corner, checking that the room is ready for the deluge of customers to come.

Getting to High Ground Organics means going through the belly of the beast of California’s agricultural sweet spot – the Central Coast. This is where high value crops are grown right to the property line, right next to towns and suburbs, cheek by jowl. The proximity to the Pacific Ocean mitigates the climate of this region so it’s never that hot and never that cold; they can grow and harvest strawberries from March to October.

Getting to High Ground Organics means going through the belly of the beast of California’s agricultural sweet spot – the Central Coast. This is where high value crops are grown right to the property line, right next to towns and suburbs, cheek by jowl. The proximity to the Pacific Ocean mitigates the climate of this region so it’s never that hot and never that cold; they can grow and harvest strawberries from March to October.