At Rock Spring Farm, we stumbled into the culinary herb business over a period of years. What started as a few plants for our own use turned into substantial plantings for a 200-person CSA. Excess capacity bled over into sales to retail stores in small bags with handwritten labels. Success in that venue led us to putting herbs in clamshells with printed labels and UPC codes, helping us to reach a wider market that turned our herb program into a corner of the farm’s success.

We learned a lot of important lessons along the way, but among the most important was that to produce herbs for sale in large volume required an entirely different set of techniques and considerations from growing herbs as a small side venture.

Getting the right herbs

In the beginning, we grew all of our herbs from seed, without regard to variety traits. German winter thyme, commonsage, and unnamed rosemary were our go-to varieties, because they were cheap. But when we started our foray into commercial production, we discovered that cheap was exactly the right word.

For commercial production, I want several traits that may or may not be important in other settings. Varieties should be slow to flower, so that they remain in vegetative growth for a longer period of time. For most herbs, when they start to flower, the eating quality of the leafy portion goes down.

To fill a clamshell nicely, or to make a bunch that looks good in a vegetable display, you want to see stems that are six to eight inches long when they are ready to cut. Often, this is the result of long internodes – the spaces between the leaves. At the same time, the stems should have a relatively “full” appearance to them, with enough leaves to look lush and beautiful.

While we initially spent a lot of effort looking for varieties with a high essential oil content, we eventually focused on plant structure and vigor instead. Because we were marketing in clamshells, the aroma of just about any variety was pretty heady when the customer opened the package; while it wouldn’t make sense to jeopardize our market by selling low-grade versions of herbs, such as Russian tarragon, it also didn’t make sense to allow oil content to trump vigorous growth and nice stems.

For most perennial herbs, the best varieties are propagated vegetatively. Seed-grown perennials are often highly variable, and not suitable for commercial production; and they usually lack the traits that I want to see for commercial herbs.

Propagation

Because I farm in the North, it wasn’t easy to buy plugs from certified organic producers in the early spring; local growers didn’t have the varieties or the quantities that we needed, and distant growers were reluctant to ship before all chance of freezing had passed. Instead, we learned to propagate our own.

For most herbs, we propagated with cuttings. To multiply tarragon, we dug up the rhizomes and potted them in the greenhouse to establish healthy transplants. Chives were similarly dug, divided, and potted up (although we often just grew these from seed, alongside our onion transplants).

To propagate from cuttings, you want new growth, but not lush growth; we found that late spring and early summer plants were the best candidates, although we did do some propagation of greenhouse-grown mother plants in late winter.

Cuttings were taken with the same short-bladed flower snips used to harvest herbs for sale. You want a nice clean cut, with no crushing. Harvested cuttings should be moved quickly to the shade, and kept cool and moist until you are ready to stick them.

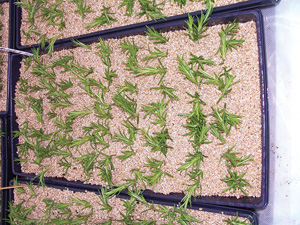

For most crops, a four-inch stem is about right. Strip the bottom half of the leaves, and simply stick the cuttings in potting soil or vermiculite. We had equal success sticking cuttings directly in 128 or 72-cell 1020 trays as we did sticking them in plain vermiculite in open flats.

Either way, unrooted cuttings need to be misted several times daily until roots form; I really like the Fogg-it brand nozzles for this job. The potting soil or vermiculite also needs to stay wet during this time. A well-vented tent of old greenhouse plastic can help reduce the plant’s attempts to photosynthesize, and reduce the extent to which it is drawing on internal nutrient resources.

We occasionally used an OMRI-approved rooting hormone as a dip before sticking cuttings. We never did side-by-side trials, and while I felt that the hormone did make some difference, it was never established as a firm part of our routine. The brand we used is no longer on the market, but there are new OMRI-approved brands available.

We typically observed rooting in 14 to 28 days. Crops rooted in vermiculite were gently pulled from the medium and placed into soil blocks or 1020 72-cell trays to grow on for transplanting in the field. Crops rooted in cell trays were allowed to grow until they had a full root ball, then planted out to the field.

As an alternative to rooted cuttings, we often used “layered” stems to grow new plants. Spreading plants grown in pots in the greenhouse or in the field will send down roots along the length of the stem. A stem can be uprooted and cut into small sections, each with a couple of roots on it. These are then potted into 72s or 128s, and grown until the roots fill the cell. This provides a fast and easy way to multiply stock purchased in two- or four-inch pots, or to propagate cuttings in late winter for farmers market plant sales.

Culture

Although we grew more than 20 different kinds of herbs, we had just three basic systems for producing them. By categorizing and standardizing our general methods, we simplified our management.

For wholesale herbs, I decided it made more sense to manage crops for rapid harvest and packing than it did to manage for maximum production. On a square-foot basis, herbs provided outstanding returns; I didn’t want to eat into those returns with extra labor trying to maximize the dollars harvested per bed. Rapid successions helped to minimize weed pressure and avoided the work of cutting back or avoiding flowering crops.

We grew our annual herbs just like we did our vegetables. The cilantro and dill we grew in the field on three fifteen-inch rows per bed (our wheel tracks were 60 inches on center), and seeded every week to ten days, just as we did our salad mix. I liked the solid band that resulted from the Planet Junior seeder. The standard shoe (rather than a scatter shoe) minimized hand weeding, increasing yields and speeding up the harvest.

Longer-season crops like parsley, marjoram, and savory we grew as transplants, with a one-month spacing between succession. We would try to place these crops in the field with other transplanted crops that would be in place for a similar amount of time.

Early basil we also grew from transplants, with early crops going in alongside the tomato crop in the high tunnels. By early summer, this crop was already getting leggy and thin-leaved because of the shade from the tomatoes. Outdoor plantings allowed us to spread out and maximize our harvest speed.

We used a second production system to manage the “simple perennials” – including thyme, sage, mints, chives, and oregano. This system was based on a three-year perennial cycle that helped us avoid the buildup of woodiness, a loss of vigor, and the invasion of perennial weeds.

To make the three-year cycle work, we would start propagating herbs around June 1 in year zero; this was past the time of lush growth that is hard to get rooted in the greenhouse, but still left enough time to get rooted cuttings started and established in the field. These new plants were planted in late summer of year zero on 30-inch rows, and not harvested. We already had the greenhouse running at this time of year to produce a variety of fall transplants, so managing the new herb plants fit into the other routines on the farm.

Harvest on the newly planted crop would begin late summer of year one, after plantings for other years had already been cut back once or even twice. In year two and year three, we continued to harvest the crop, maintain the plants, and control weeds. In year four, we harvested the crop hard and removed it in early summer.

For most of the simple perennials, we planted a new crop every year, so that we always had crops of several different ages in the field.

Because they spread so rapidly and vigorously, spearmint and peppermint require some special management. We expected the two rows to completely fill the bed by the middle of the second year, which made weed control more difficult in the centers of the bed. We often maintained the two beds on either side of a mint bed as part of our annual rotation, so that when we tilled for planting or cultivated the wheel tracks, the mint runners were cut back. Because mints are relatively easy to propagate and grow vigorously, we occasionally shortened the three-year rotation down to two years.

In the early years of the herb program, we would try to plant just enough to meet market demand. Later, I decided that it didn’t make sense to plant less than a full bed of any of the Big Eight herbs – chives, spearmint, oregano, thyme, sage, basil, and dill (rosemary is the last member of the big eight, but we couldn’t grow it outdoors with our frigid Minnesota winters). Rather than complicate our management or risk running short on supply, we planted with abandon to grow at well over our market demand, which allowed us to take on new markets and manage for speedy harvests.

These simple perennials are great herbs for the CSA – they add lots of perceived value to a box, but are relatively easy to manage.

Rosemary and tarragon made up the “complex perennials” at Rock Spring Farm. Rosemary because it isn’t hardy in our climate, and tarragon because it slow to establish.

To grow rosemary, we kept our greenhouse just below freezing all winter, and grew the rosemary in pots. A new crop was started every year in plugs, then moved up through 1-gallon, 3-gallon, and finally 15-gallon pots over a period of several years; the last year before discarding a plant that had grown too large for its pot, we picked it brutally hard for Thanksgiving and Christmas herb sales.

Tarragon was grown on a single row in each 60-inch bed, and allowed two full years to establish itself before serious harvest got underway.

Next month: Harvest and postharvest handling of herbs.

Chris Blanchard provides consulting and education for farming, food, and business through Flying Rutabaga Works. As the owner and operator of Rock Spring Farm in northeast Iowa since 1999, Chris raised 20 acres of vegetables, herbs, and greenhouse crops, marketed through a 200-member year-round CSA, food stores, and farmers markets. Prior to 1999, Chris managed student farms, worked as an intern, packing house manager, plant breeding assistant, and farm manager, and provided consulting for a major organic processor, in California, Wisconsin, Iowa, Maine, and Washington state. His workshops, writing, and consulting throughout the country about farm business concepts, food safety, organic vegetable production, and scaling-up have gained a reputation for fresh approaches, down-to-earth information, and honesty.

Chris Blanchard, one of the leading lights of the organic farming world, passed away on October 28 from cancer. He leaves an impressive body of work that will help market farmers far into the future.

Chris Blanchard, one of the leading lights of the organic farming world, passed away on October 28 from cancer. He leaves an impressive body of work that will help market farmers far into the future.

.svg.png)